You are here:

- CMP Home >

- Web Exhibits >

- Stereoscopic Images >

- Mining

- SUBJECT:

- COMPANY:

- GEOGRAPHIC LOCATION

Stereoscopic Images of Cleveland in 3-D

Mining (Coal and Iron Ore)

- This gallery contains 8 slides. Click on the arrows to advance to the next or previous slide.

- Click on the the photo to see the 3-D rendering.

- To view the total effect of the 3-D versions of the images use anaglyph 3-D Glasses (red/cyan).

-

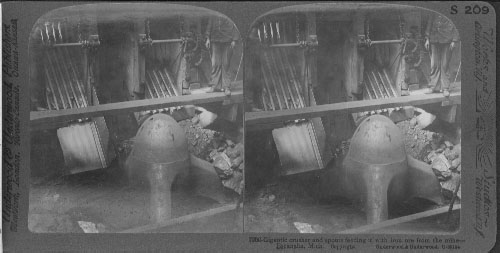

Gigantic Crusher and spouts feeding it with iron ore from the mine - Escanaba, Mich.

We are on the premises of the Oliver Iron Mining Company at Escanaba (norther Michigan). Here the ore-bearing rock taken from Michigan iron mines is crushed by this powerful machinery to get it into shape so it can be handled more easily and with greater economy of space. The economic importance of the process can be inferred from the fact that the company spends $2,000,000 just to install the plant, besides undertaking the expense of running and repairs.

Those spouts let the ore down from huge bins where it is stored when it first comes down from the mine. The crushers in this one establishment can grind yp 4,000 tons a day, ready for shipment east by Lake steamer. A considerable part of the eastern shipments go to Lake Erie ports and are then transferred to trains for the huge blast furnaces and steel mills of the Ohio Valley region (Pittsburgh, Youngstown, etc.). This giant crusher is getting raw material ready for the biggest of all America's enormous manufacturing industries.

For a sight of miners at work 140 feet below the ground, getting out iron ore, use Stereograph 7947. For the unloading of a Lake steamer, use 7970. For the melting of ore in a blast furnace, 5520. For the shaping of a 90 ft. beam of red-hot steel, 5523. -

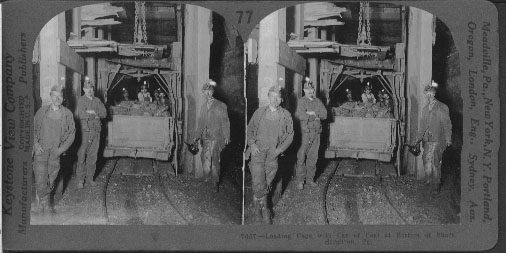

Loading Cage with Car of Coal at Bottom of Shaft, Scranton, Pa.

Here you are at the bottom of an anthracite, or hard coal mine. This is the lower end of the large shaft which leads to the surface of the earth perhaps 1,500 feet above. A carload of coal is on the elevator or cage ready to be lifted to the top of the dump into the breaker. The cage and the shaft are the center of a mine of this kind. To it lead the many switches from acres of underground rooms. It is necessary that this shaft be constructed of strong materials. For not only must all the coal be brought to the surface through it, but it is the only exit of the hundreds of miners.

You can see for yourself that the shaft and cage here shown are strongly made. You will observe the large timbers, the heavy framework of the cage, and the big safety chain above. The weight on the cage you can figure for yourself. The car weighs one ton and the coal two tons. The cage weights 1 1/2 toms and the 1500 feet of wire rope, which lifts it, another 1 1/2 tons. How much is this in all? You will be interested to know that the rope is made of strands of woven steel wire, 19 wires to the strand. It is 1 1/8 inches in diameter and can lift a weight of 60 tons. Some of the cages used in these mines have two decks, one about the other. By this means, two cars of coal can be lifted at a time.

Some of the Pennsylvania shafts are sunk 3,000 feet beneath the surface of the earth. This means that some of the coal is actually mined below sea level. In many of these deep mines it is necessary to have extensive pumping equipment to remove the inflow of water. Pennsylvania mines, however, are shallow as compared with most of those in Europe. Some of the European mines are over a mile in depth. -

Iron Ore Being Taken from an Open Pit Mine, Hibbing, Minn.

This steam shovel is scooping up iron ore in an open-put mine in the Mesaba Range in Minnesota. This is the most valuable iron region known in the world. Most iron is hard rock and must be blasted. It must also be mined underground. But in this unusual mountain range the iron ore is so near the surface and so soft that it can be mined with steam shovels such as you see in this picture. This shovel is cutting a trench several yards wide. It is loading the ore it removes into those cars near by. This shovel can load one of those cars in about three minutes. Each year the Mesaba Range mines furnish one-third of the world's supply of iron. The Mesaba, The Vermilion, and Cuyuna Ranges, all in northern Minnesota, enable the United States to lead the world in iron and steel industries.

At one time all the iron ore from this district was shipped to the eastern coal fields. This was economical because it takes two tons of coal to smelt every ton of ore. However, instead of allowing the ore boats to return empty they were finally used to bring back coal so that some of the smelting could be done in the iron districts.

Iron and steel, which is a form of iron, are so necessary to us today that if all iron suddenly disappeared we would have to live almost as savages do. Our tools, machinery, screws, nails, ships, engines, automobiles, car tracks, frame work for large buildings, stoves, and many other things are made wholly or partly of this important and valuable metal. -

Stripping Anthracite Coal, Penna.

When a vein of coal lies near the surface of the earth it is mined in the way shown in this picture. All the dirt on top of the coal is removed by big steam shovels, one of which you can see at work. The dirt so removed is called strippings. The machines which do this work weigh almost fifty tons and remove strips of earth about twenty-five feet wide and ten feet deep. The stripping is hauled away in small cars. Notice that more earth had been removed in the center of the view. There the vein of coal is uncovered and can be taken out from the top. All that great hill of earth on the left must be cleared away, but great as the work is, it is cheaper to do it than it is to sink shafts into the ground and do the mining underground.

By the stripping method all the coal can be mined, but in mining from shafts supports of coal must be left at certain distances apart to hold up the ceiling. Mining from shafts, sunk from the surface of the earth downward, or into the side of a hill, is the more common way of coal mining because most coal is not near enough the surface to be reached by the stripping method.

Which method of mining do you think the miners prefer?

Where are the anthracite coal mines of this country? -

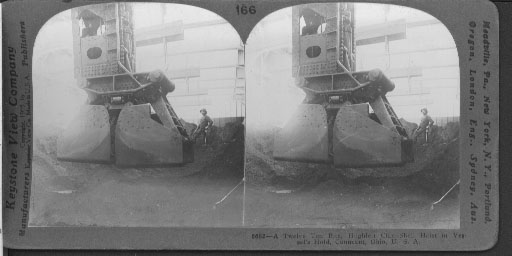

A Twelve Ton Bite, Hughlette [sic] Clam-Shell Hoist…, Conneaut.

Twelve-Ton Bite: The huge bucket has descended from its position in view 6681 through the hatchway into the hold of the vessel. The operator moved a lever, the piston-rod seen in 6681 ascended into its jacket, the great jaws closed upon 12 tons of ore and the length of the bucket from right to left was reduced from 22 feet to 9 feet. The machine to which the bucket is attached is now in the position of the second machine shown in view 6680. In less than thirty seconds the operator, by moving his levers, will cause the load to rise above the deck, the machine to back into the position of the first one seen in view 6680, and the load to drop into the transfer car. This great machine delivers its huge loads to the stock piles at the rate of one load per minute. The average load is 10 tons.

This is the hold of a modern ore boat capable of carrying 12,000 tons of ore. Only four such boats have yet been built. They are 650 feet long and 52 feet wide. The hatchways are twelve feet apart. The deck is supported by steel arches from the side of the boat. This makes the hold of the vessel one great room unobstructed by partitions or pillars of and kind. This room is 400 feet long, 50 feet wide, and 32 feet high. The numerous hatchways enable the unloaders to do the work with little or no hand labor in the hold. The Hulett bucket may be turned by its operator in and direction and moved back and forth along the hatchway at his will. -

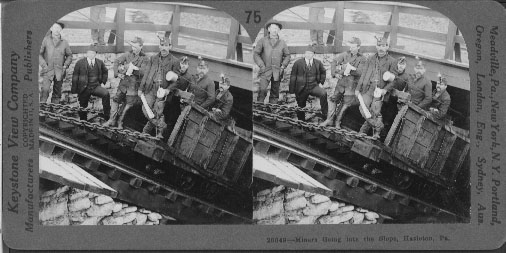

Miners Going into the Slope, Hazleton, Pa.:

You see here a crowd of miners on a car ready to be lowered into a Pennsylvania coal mine. Inside the shaft, running directly down into the earth, there is a tunnel, or slope, as it is called, leading into the mine. On cats such as the one here shown coal is brought to the surface from far back in the mine. A stationary engine furnishes the power to drag the cars up the steep incline.

The scene is rich in suggesting the life of coal miners. On top of the caps of the men are lamps, some of which are already lighted. Oil is burned in these little tin lamps. One of the miners has on rubber boots, because there may be water in certain parts of the mine. Most of the men seen here are foreigners. The overseer or "boss" of the mine is easy to find.

If you were to go with these miners you would likely find that the slope was built through a vein of coal. Sometimes, however, the vein is tapped by cutting through dirt and rock. At any rate, when the slope comes to the coal vein, it winds about in the heart of the vein. Leading off from either side of it are long tunnels in which switches have been built so that the cars can be run off to the various rooms and there loaded.

The life of these miners is not east. They are well paid, the amount they receive annually depending on the amount of coal they mine. But it is lonely work. All day long, with drill, pick, and shovel, they labor steadily. Sometimes an accident happens. Gases form in some of the mines, and these are set on fire by the lights on the miners' caps. An explosion occurs. Sometimes many miners are cut off far below ground. Rescue parties may work for days in an attempt to save their lives. -

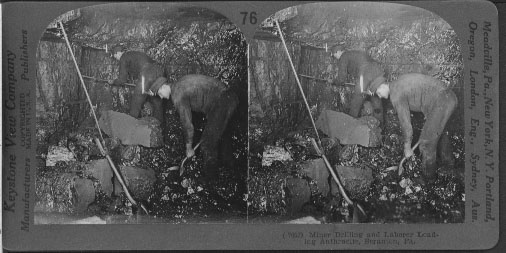

Miner Drilling and Laborer Loading Anthracite, Scranton, Pa.

Here you see a miner and his helper working in a coal mine. The miner contracts with the company to mine the coal for so much per car or per ton. He furnishes his own tools, pays for the powder with which to blast the coal loose, and hires a helper to assist him at so much a day or so much per ton.

The miner in the background is drilling a hole in the solid layers of anthracite, making ready to put in a blast of powder. The helper is busy shoveling the loose coal into a car which will carry it to the elevator. From there it will be taken to the surface where there is a coal breaker. You will observe that each man has a tin lamp fastened to the front of his cap. What looks like candles sticking up from these lamps are the sheets of flame.

This scene was taken with a flashlight, so the mine appears to be very well lighted. As a matter of fact, it is pitch dark in here. The lamps from the miners' cap make just enough light to cast queer-looking shadows in all the corners. How would you like this kind of work, far below ground in the dark?

Anthracite is the coal we call hard coal. The soft coal is called bituminous coal. The anthracite district of the United States is a small area, and Scranton is in the very heart of it. Soft coal is found in many states. Pennsylvania leads in the production of both kinds. In the United States, but little anthracite is found outside of Pennsylvania. West Virginia, Illinois, Ohio, Kentucky, Indiana, and Alabama are our most important producers of soft coal. The value of bituminous coal in the United States in 1915 was over $500,000,000. The value of the anthracite was $185,000,000. -

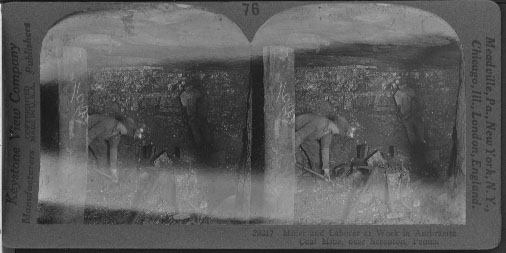

Miner and Laborer at Work in Anthracite Coal Mine, Scranton, Pa.

No accompanying text available.

3D version not available.